Text File

Text file connections involve importing data from static text files (tab delimited content) The data shall be imported within a Form that either exists already or has been designed specifically for the purposes of data import.

Note that the if the first two columns of the text file are SYS_BUSINESS_NUMBER and SYS_DOC_VERSION then the system will attempt to find a matching record with the same Number and Version before creating a new record. If a match is found then the system shall update that record with the values provided, otherwise, a new record shall be created.

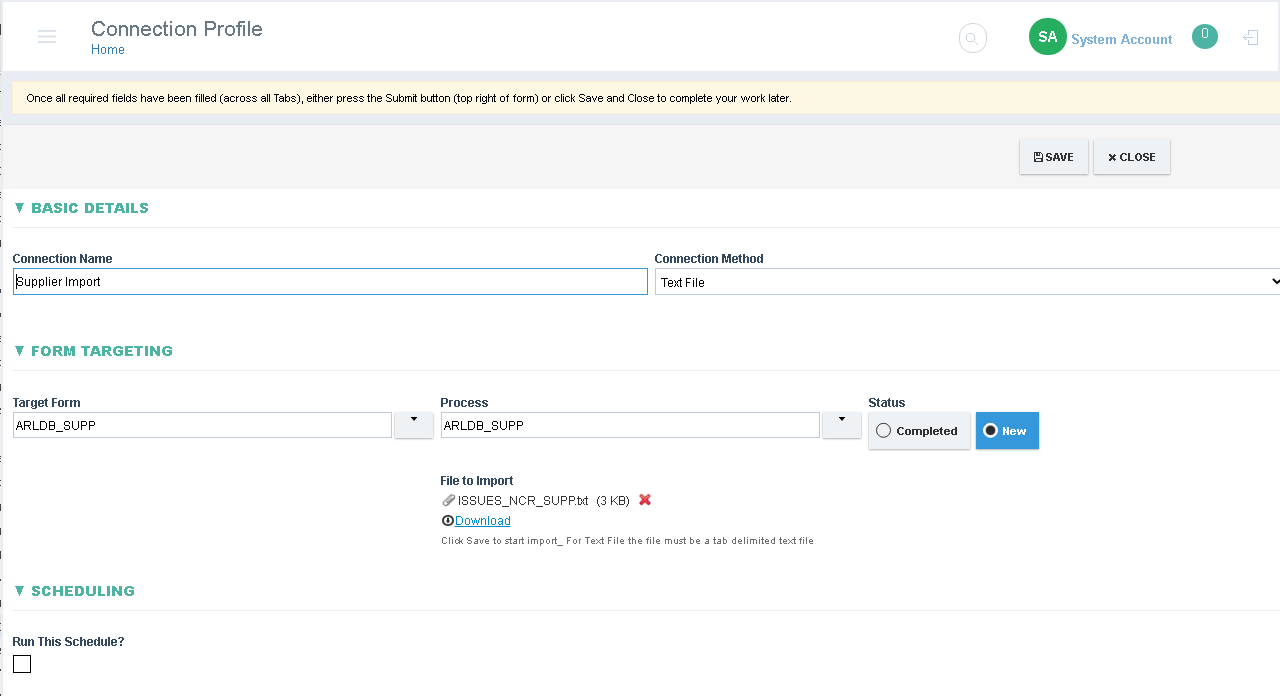

Sample Connection

Field Details:

- Connection Name: Display name of the connection.

- Connection Method: Set to Text File, available options (Database, Database - No Import, Form, Java, Manual, Text File, View, XML File, Xquery)

- Target Form: Form where the data will be imported

- Process: Which process to associate for each record that has been imported

- Status: Is the record to be imported in the first step of the process (New) or the last step (Completed)

- File To Import: If the connection is not being run on a schedule, then, a file can be uploaded for import (file contents to be tab delimited)

- Import File Directory: If the connection is being run on a schedule, then, a file import directory can be specified where all text files in that directory shall be imported

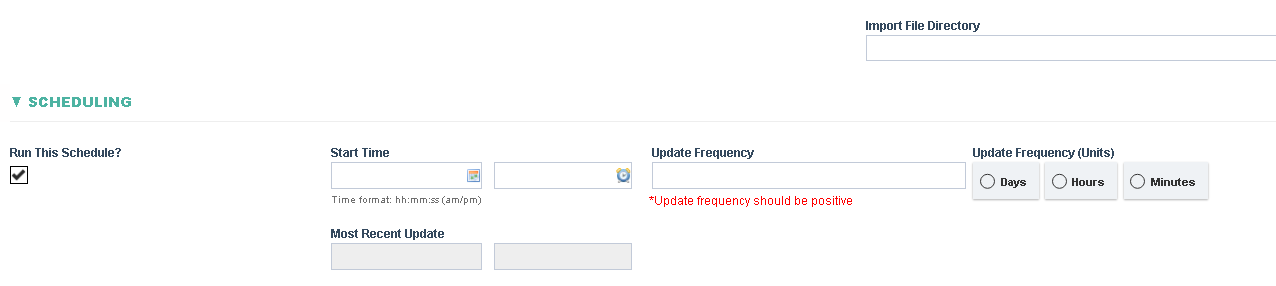

- Run this Schedule?: If set, then the connection will run at the specified schedule, otherwise the connection shall run on each save.

- Start Time: Date and time when the connection shall be scheduled from

- Update Frequency: The repeat frequency combined with the Update Freuency (Units), for e.g if the connection is to be run hourly then set this field to 1 and the Units field to Hours

- Update Frequency (Units): Days, Hours and Minutes. Used in combination with Update Frequency field

- Most Recent Update: This is the Date and Time when the connection was last run

Sample Text File:

|

SYS_BUSINESS_NUMBER |

SYS_DOC_VERSION |

DOCCON_DOC_TITLE |

DOCCON_MAIN_DOC_ID_TYPE |

DOCCON_MAIN_DOC_ID_CATEGORIES |

DOCCON_MAIN_DOC_ID_REVIEW_DATE |

DOCCON_MAIN_DOC_ID_EFFECTIVE_DATE |

DOCCON_MAIN_DOC_ID_DEPARTMENT |

DOCCON_MAIN_DOC_ID_ORIGINATOR |

DOCCON_MAIN_DOC_ID_OWNER |

DOCCON_MAIN_DOC_ID_REVIEWERS_LIST |

DOCCON_MAIN_DOC_BODY_ATTACHMENT |

|

Number |

Version |

Title |

Document Type |

Categories |

Review Date (YYYY-MM-DD) |

Effective Date (YYYY-MM-DD) |

Department |

Author |

Approvers (multiple values to be separated by semi colon ';') |

Reviewers (multiple values to be separated by semi colon ';') |

Draft Attachment |

|

IMP-00001 |

1 |

Handling of Retention Samples |

Procedure |

4 Quality management system : 4.1 General requirements |

2019-07-01 |

2017-07-01 |

Administration |

Nick Taylor |

Nick Taylor |

Nick Taylor |

C:/upload/FileName.docx |

|

IMP-00002 |

1 |

Synergy Site-Wide Monitoring System |

Procedure |

4 Quality management system : 4.1 General requirements |

2019-07-01 |

2017-07-01 |

Administration |

Nick Taylor |

Nick Taylor |

Nick Taylor |

C:/upload/FileName.docx |

|

IMP-00003 |

1 |

Monitoring and Measurement of Process |

Procedure |

4 Quality management system : 4.1 General requirements |

2019-07-01 |

2017-07-01 |

Administration |

Nick Taylor |

Nick Taylor |

Nick Taylor |

C:/upload/FileName.docx |

|

IMP-00004 |

1 |

Monitoring and Measurement of Product |

Procedure |

4 Quality management system : 4.1 General requirements |

2019-07-01 |

2017-07-01 |

Administration |

Nick Taylor |

Nick Taylor |

Nick Taylor |

C:/upload/FileName.docx |

|

IMP-00005 |

1 |

Post Market Activities Managing Global Vigilance and Post-Marketing Surveillance |

Procedure |

4 Quality management system : 4.1 General requirements |

2019-07-01 |

2017-07-01 |

Administration |

Nick Taylor |

Nick Taylor |

Nick Taylor |

C:/upload/FileName.docx |

Example of Importing Data with Repeating Sections and/or Grids (note that Repeating Sections and Grids must be given unique IDs (SYS_RECORD_ID) of their own)

|

SYS_BUSINESS_NUMBER |

SYS_DOC_VERSION |

MASTER_EQUIPMENT_MAIN_DETAILS-SYS_RECORD_ID |

MASTER_EQUIPMENT_MAIN_TYPE |

MASTER_EQUIPMENT_MAIN_TITLE |

MASTER_EQUIPMENT_MAIN_TIME_REQ |

MASTER_EQUIPMENT_MAIN_COST_EST |

MASTER_EQUIPMENT_MAIN_EVERY_TIME |

MASTER_EQUIPMENT_MAIN_EVERY_TIME_TYPE |

MASTER_EQUIPMENT_MAIN_LAST |

MASTER_EQUIPMENT_MAIN_NEXT |

MASTER_EQUIPMENT_MAIN_RESP |

MASTER_EQUIPMENT_MAIN_TASK_DETAILS-SYS_RECORD_ID |

MASTER_EQUIPMENT_MAIN_TASK_NAME |

MASTER_EQUIPMENT_MAIN_TASK_INSTR |

|

Equipment Number |

Version |

Record ID |

Maintenance based on |

Maintenance Title |

Time Required (hours) |

Cost Estimate |

Every |

Unit |

Last Maintenance performed on |

Next Maintenance Due On |

Person Responsible |

|

Task |

Instructions |

|

EQUIP-11111 |

0 |

EQUIP-11111-1 |

Time |

Calibration |

|

|

1 |

Day(s) |

|

|

|

EQUIP-11111-1-1 |

Do this |

Daily Rounds Log |

|

EQUIP-11111 |

0 |

EQUIP-11111-2 |

Time |

Preventative Maintenance |

|

|

1 |

Month(s) |

|

|

|

EQUIP-11111-2-1 |

And this |

-Inspect general condition of the unit and check unit for unusual noise or vibration -Inspect air inlet louvers/Combined inlet shields -Check and adjust water level in basins -Check operation of make-up valve -Check and adjust bleed rate -Check Belt Condition |

|

EQUIP-11111 |

0 |

EQUIP-11111-3 |

Time |

Re-Qualification |

|

|

1 |

Year(s) |

|

|

|

EQUIP-11111-3-1 |

And this also |

-Conduct the inspection on Form ITP-EC and file the document in the MI binder/file. -Inspect unit finish -Check drive alignment |

|

EQUIP-11111 |

0 |

EQUIP-11111-4 |

Time |

Water Testing |

|

|

6 |

Month(s) |

|

|

|

EQUIP-11111-4-1 |

More of this |

None Specified by Mfg. |

|

EQUIP-11111 |

0 |

EQUIP-11111-5 |

Time |

Environmental Monitoring |

|

|

3 |

Month(s) |

|

|

|

EQUIP-11111-5-1 |

More of that |

-Inspect cold water basin/Spray nozzles -Drain basin and piping -Adjust belt tension -Lubricate fan shaft bearings -Lubricate motor base adjusting screw -Check and lubricate optional gear drive -Check motor voltage and current -Clean fan motor exterior -Check general condition of the fan -Check and unplug fan drain holes (hollow blade fans) -Check fan for uniform pitch -Check fan for rotation without obstruction -Check and recoat steel shafts with RUST VETO® |